CIP - Cleaning in Place : Good Practices

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. Introduction

2. Fundamental principles of CIP : 4 Ts

1. Introduction

In food industries having a clean process is a must. This ensures the hygiene level inside equipment is good enough for selling a safe product to consumers. Cleaning must be done regularly, sometimes several times per day. It can be necessary to clean for example at product changeover to avoid cross contamination, at regular intervals while producing a same product to make sure no material can stay too long in pipes and equipment and start to spoil. It can be required to clean before an installation stoppage, for example before the weekend.

Manual cleaning, where pipes are taken to a cleaning station, tanks accessed and cleaned can be viable for small installations not requiring cleaning too often, but plant operators will quickly realize that manual cleaning will lead to high labor requirement, long cleaning time and thus stoppage, and sometimes improper cleaning.

Considering an automated system that will allow to clean an installation without dismantling it and without manual intervention can thus quickly become mandatory to ensure both quality and productivity. This is what a Cleaning In Place (CIP) system can allow. Designing such system involves following several good practices that will make the process safe and efficient.

This page is focusing on key good practices to apply to design a CIP system.

2. Fundamental principles of CIP : 4 Ts

CIP systems are based on circulating several cleaning solutions inside the process to clean pipes and equipment. It is however not sufficient to circulate any cleaning product in any condition in order to arrive to an acceptable results that needs also to be repeatable.

To achieve proper cleaning, the following must be respected when designing and operating a CIP system :

- Time

- Temperature

- Titration

- Turbulence

2.1 Time

This can look obvious but in practice may not be really respected because of misunderstanding or simply because of pressure to produce as soon as possible : cleaning needs time.

It is not because we circulate a cleaning solution a couple of minutes that it is enough, the cleaning solution will need time to properly diffuse and penetrate the material to remove, then perform its chemical action on the "dirt", then remove it by entraining the broken down material with the cleaning solution flow.

The time required must be determined by experience while performing cleaning validations. It should not be too short to ensure good cleaning but the plant operator should also be mindful of the total cleaning time to make sure it does not decrease too much the capacity of the line (no production while performing CIP).

Top

5 Most Popular

1. Pressure drop

2. Reynolds Number

3.

Pressure drop K coefficients

4. Churchill equation

5. Moody diagram

2.2 Temperature

Heating will tremendously increase the efficiency of cleaning, especially when applying chemicals. Typical heating temperature will be around 70-80c for cleaning solutions such as alkaline and acid solutions. It is important not to heat higher than that though for safety reasons, avoiding to have boiling corrosive liquids.

When using water for rinsing after passing cleaning solutions, ambient temperature is fine.

2.3 Titration

It is important to have the right concentration of caustic and acid in order to have a good effect on the product to clean in pipes and equipment. A too low concentration will have a low effect but it is important to understand that too high of a concentration will also have a lower effect and will lead to longer cleaning time ; additionally using high concentration will increase the cost of the cleaning step without improving its efficiency.

The optimum should be determined by experience.

It is also important to understand what should be the sequence of cleaning, especially if an acid step is needed or not, which is not always the case. The required chemical to apply can be estimated by looking at the composition of the product to clean :

| Product to clean | Water | Alkaline solution | Acid solution |

| Lactose | + | - | - |

| Starch | - | + | + |

| Fibers | + | = | = |

| Sugars | + | + | - |

| Fat / oil | - | + | + |

| Proteins | - | + | + |

| Mineral salts | = | = | + |

A typical cleaning sequence would be :

- Water rinsing

- Alkaline step (typically caustic ~2% solution)

- Water rinsing

- Acid step (typically phosphoric or nitric acid ~1% solution)

- Water rinsing

A step may not be required, for example if the product is mainly made of sugars, maybe the acid step is not needed.

SAFETY : Safety in CIP is extremely important, hot corrosive solutions are used, alkaline and acid solutions are also not compatible. It is mandatory to perform a process risk assessment and to enforce proper PPE for the operators.

2.4 Turbulence

When we think of an operator cleaning a pipe or a tank, we realize that he needs energy to remove dirt, even if he has soaked the product with cleaning chemicals. In CIP, the energy is brought in the form of turbulence of the fluid, the fluid movement will help to remove the product to clean and to carry it away.

In order to ensure a turbulence good enough for cleaning, the velocity in the pipe must be > 1.5 m/s.

It is thus required to design the CIP pumps in accordance to the pipe diameter in order to reach this velocity.

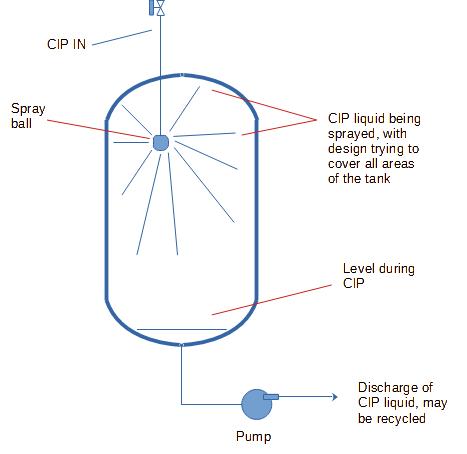

However one must notice that processes are not only made of pipes... Pipes are merely here to link equipment. To clean pipes, it is necessary to install spray balls. There are different design existing but for each spray balls it is important to be able to ensure the right pressure at the ball inlet, this what will allow to have a proper ejection of the fluid from the ball then impact and shear stress on the wall, which is the corresponding effect to turbulence in pipes. While cleaning a tank by CIP through a spray ball it is important to constantly drain the tank to avoid level accumulation that would prevent a good cleaning ; a 1st "soaking" step may however be necessary before the full cleaning cycle.

3. Other considerations for a good CIP

Ensuring the 4Ts is the absolute minimum for a good cleaning. If one of the Ts is not here, it will be impossible to have a satisfactory cleaning. However the design of the installation will also have an influence to make cleaning more or less easy.

The manufacturing process of a food product must be design with hygiene in mind. Hygienic design includes but is not limited to :

- Hygienic equipment design

- Hygienic building design

- Hygienic pipe design (some examples below, please follow the link to know more)

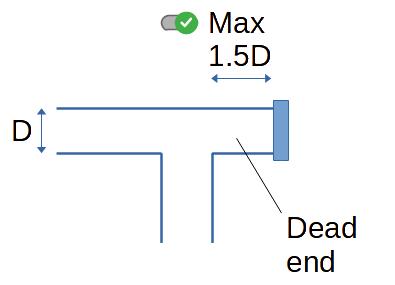

| No dead ends with length > 1.5*pipe diameter |  |

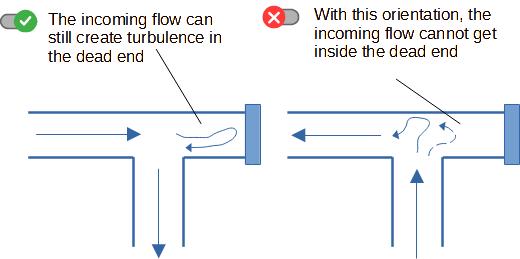

| Dead end must be orientated to promote flow as much as possible |   |

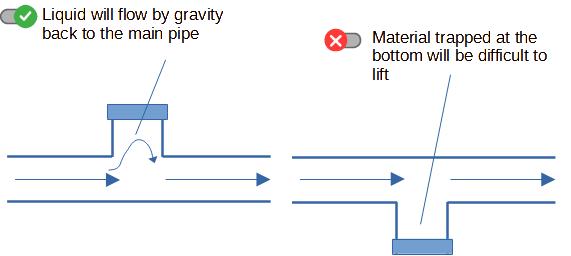

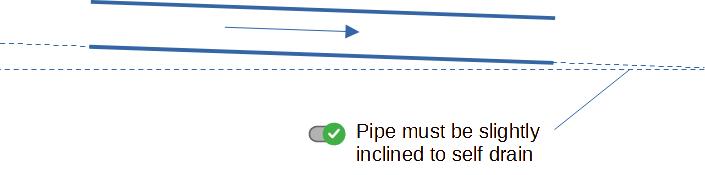

| Pipe must be straight and slightly inclined to self drain |  |

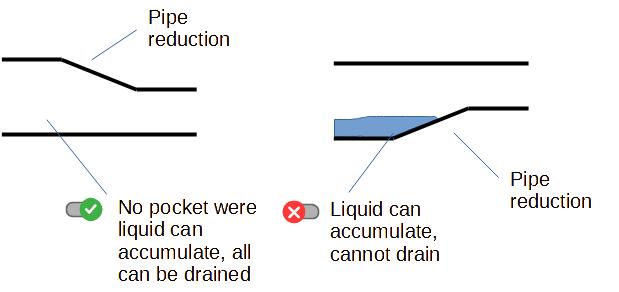

| Pipe reduction must be designed to be excentric, with diameter change from the top |  |