Tank purging

Dilution purging, Displacement purging, Pressure-Cycle purging, Evacuation-Replacement purging

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

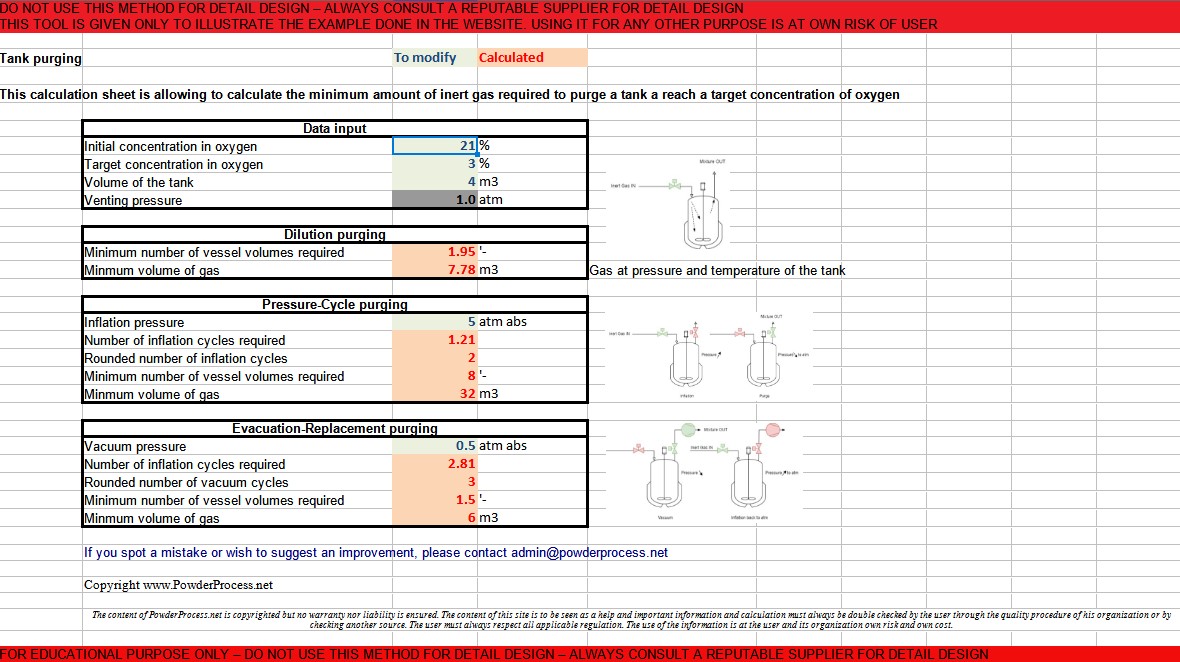

1. Dilution purging

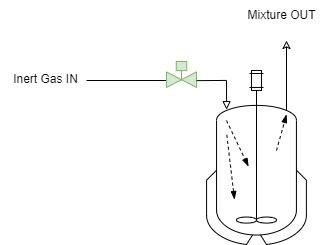

2. Displacement purging

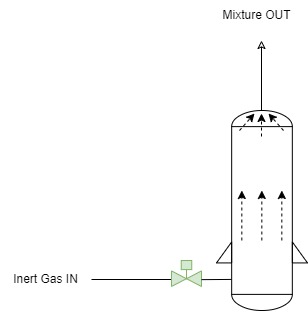

3. Pressure-cycle purging

4. Evacuation - Replacement purging

5. What is the most efficient purging method ?

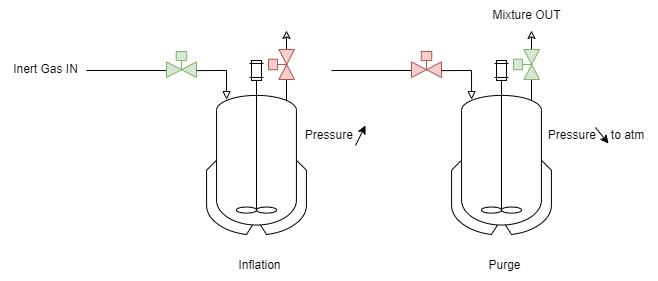

6. Tank Purging - Minimum required gas volume Excel calculator

In process industries, it can be required to ensure that the concentration of oxygen in a tank is below a certain amount. This can be to protect the product, for example from oxidation, this can be also for safety reasons to make sure that the substance in the vessel, typically a hydrocarbon, cannot burn. There are different methodologies involving purging with an inert gas (nitrogen for example) to ensure the oxygen level is lowered, this page is reviewing them.

1. Dilution purging

In this form of purging, an inert gas is simply blown through a vessel. The inert gas is mixing with the original gas (air) and is leaving through the vent of the tank, carrying part of the original gas with it. There are different conditions for this kind of purging to be efficient :

- The gas flow must be sufficiently high to mix well with the air inside the tank

- The inlet of the inert gas must be such that the gas flow can reach the bottom of the tank

- The inlet and the vent must be far from each other to avoid any kind of bypass

- The vessel must be simple, there should not be any kind of dead areas where the incoming gas could not reach

Assuming the inert gas has no oxygen in it, the minimum amount of gas to be injected to purge the tank can be calculated thanks to :

Vn = ln (Ci/Cf)

With :

Vn = number of vessel-volumes of inert gas required

Ci = initial concentration of oxygen in the tank

Cf = final required concentration of oxygen in the tank

The volume of gas is at the conditions of pressure and temperature of the reactor.

Note that it is a minimal amount. In practice it is likely that more will be required as none of the conditions above can be 100% met. It is important to check the actual concentration of oxygen in the tank once the purge sequence is completed. If this procedure is done often, inline analysers may be used.

2. Displacement purging

Displacement purging is assuming that the gas movement in the tank can be plug flow. The inert gas is injected slowly on one end of the tank while air is removed at the other end. To have this kind of piston movement it means that the tank must have a very specific shape, typically a narrow cylinder. This can also be used to purge a pipe but it is recommended to have the help of a pig to that will help separate the air from the inert gas and allow to have the plug flow.

The minimum amount of inert gas is then equal to the volume of the tank. A minimum safety factor of 20% is recommended. It is also recommened to analyse the residual level of oxygen in the tank before filling it with the actual product.

3. Pressure-cycle purging

This mode of purging a reactor is different than the previous ones. Here the inert gas is injected to a closed vessel, which means that the pressure will increase. Once the target pressure is reached, the injection of inert gas is stopped, then the vent of the tank is opened to release the excess pressure and thus a mix of air and inert gas.

This method can only be applied if the vessel is able to withstand pressure.

The number of cycles to perform to reach the target oxygen concentration can be calculated thanks to :

Cf = Ci*(1/P)n

With :

Venting pressure is assumed to be 1 atm

Ci = initial concentration of oxygen in the tank

Cf = final required concentration of oxygen in the tank

P = pressure reached at each cycle (atm abs)

n = number of cycles done

Once n is calculated thanks to Ci, Cf and P, the minimum volume of inert gas to be used can be calculated thanks to :

Vn = n(P-1)

With :

Vn = number of vessel-volumes of inert gas required

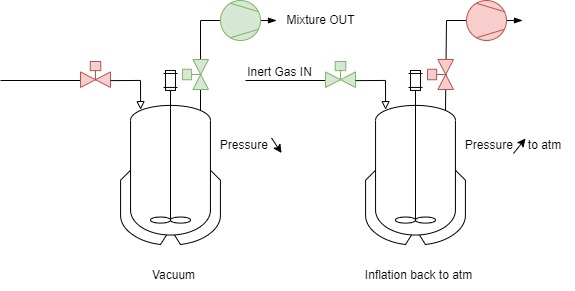

4. Evacuation - Replacement purging

This method is also based on cycles of injecting the inert gas and venting out the mixture, however instead of going in pressure, this time vacuum is used. A vacuum is created in the vessel, then the vacuum is broken by injecting the inert gas, then a new vacuum is applied...etc...

Top 5 Most

Popular

1. Compressor

Power Calculation

2. Pump Power Calculation

3. Pipe Pressure

Drop Calculation

4. Fluid Velocity in pipes

5. Churchill Correlation

(friction factor)

This assumes that :

- The tank is able to withstand vacuum

- The tank is connected to a vacuum pump

The minimum amount of inert gas to be used is calculated in a similar way as pressure cycle purging. The formula below is assuming that the vacuum is broken by reaching again atmospheric pressure.

Cf = Ci*(P/1)n

With :

Venting pressure is assumed to be 1 atm

Ci = initial concentration of oxygen in the tank

Cf = final required concentration of oxygen in the tank

P = pressure reached at each cycle (atm abs)

n = number of cycles done

Once n is calculated thanks to Ci, Cf and P, the minimum volume of inert gas to be used can be calculated thanks to :

Vn = n(1-P)

With :

Vn = number of vessel-volumes of inert gas required

5. What is the most efficient purging method ?

It is quite difficult to answer to this question as very often, the choice will depend on the mechanical capabilities of the vessel to inert. If the tank has no resistance to pressure nor vacuum, dilution purging will have to be used but in practice all the conditions mentioned for a good dilution purging may not be met which means that the actual volume of gas to be used will be much larger than the minimum volume calculated above. If a tank has some resistance to pressure, pressure-cycle may actually be quicker and more efficient even if on paper it consumes more gas. If the tank is able to withstand vacuum, installing a vacuum pump for evacuation replacement purging will be advantageous.

6. Tank Purging - Minimum required gas volume Excel calculator

MyEngineeringTools.com has developed a free Excel calculator that allows you to calculate the minimum volume of inert gas to be used to purge a vessed : Tanks Purging calculator Excel

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.