Gas Pipeline : calculation of flow and pressure drop in long

pipelines

How to calculate the flow of compressible fluid (gas) in long pipelines ?

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

1. Isothermal equation

2. Weymouth equation

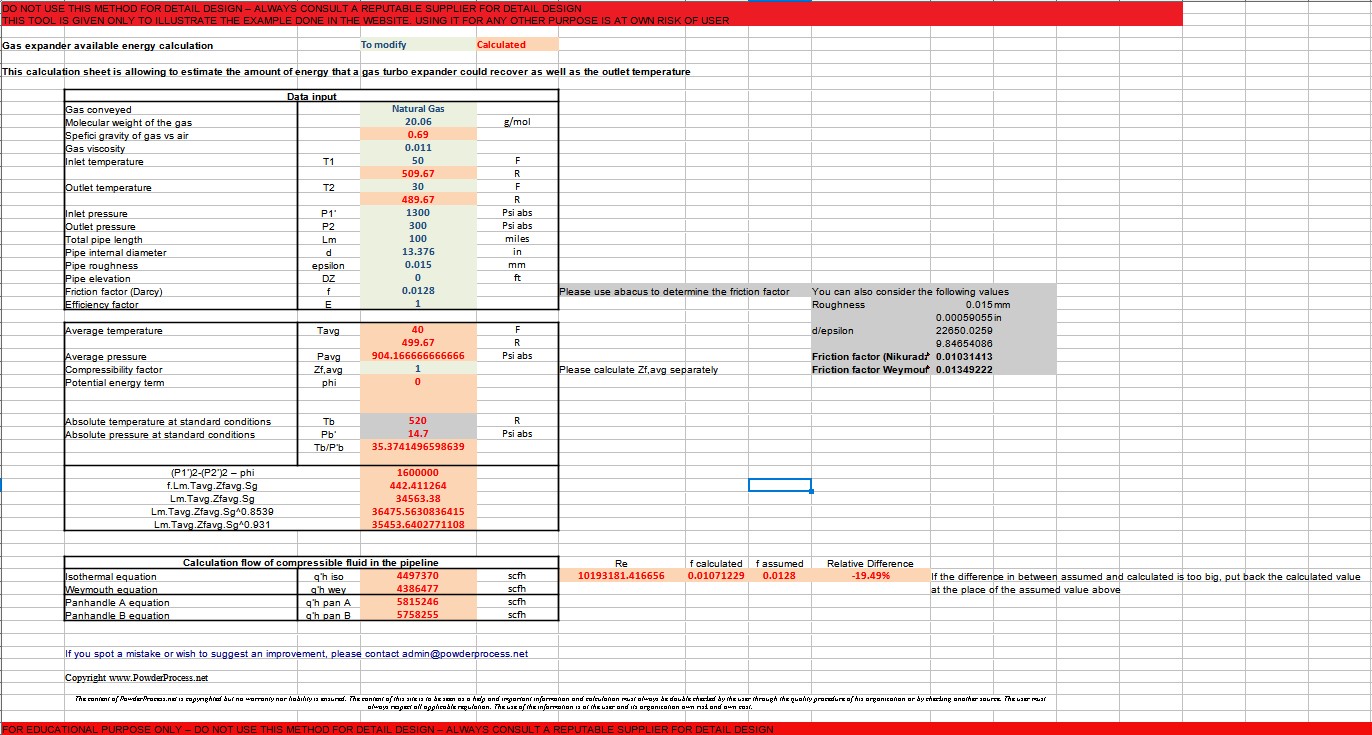

5. Long pipelines gas flow Excel calculator

At the scale of a factory, regular Darcy equation can be used to calculate the pressure drop of compressible fluids in pipe provided the calculated pressure drop is < 40% of the inlet pressure :

- If the pressure is <10% of the inlet pressure, the density of the gas at the inlet can be used in the calculation

- If the pressure is in between 10 and 40% of the inlet pressure, the average of the density of the gas at the inlet and the outlet can be used

However if the pressure drop is higher than 40% of the inlet pressure, which can happen in long pipelines (natural gas pipeline for instance) then other equations should be done. The objective of this page is to detail which equations can be used in this case.

1. Isothermal equation

Calculate pressure drop via Isothermal equation

The 1st equation that is often referred to for calculations with significant pressure drop (>40% of inlet pressure) in long pipelines for gases is the isothermal equation. This can be used if the following assumptions can be done :

- The flow is isothermal

- No mechanical work done

- Steady flow

- Perfect gas law can be applied to the fluid

- The velocity can be modelled as the average velocity at a cross section

- The friction factor is constant all along the pipe

- The pipe is straight and horizontal

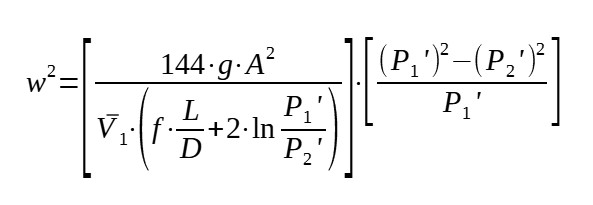

If those conditions are met, the characteristics of the flow can be determined by solving the following equation (complete isothermal equation) :

With :

w = flow rate of gas in pipeline (lb/s)

g = gravitational acceleration (32.174 ft/s2)

A = cross sectional area of the pipe (ft2)

V1 = specific volume of the fluid (ft3/lb)

f = friction factor

L = Length of the pipe (ft)

D = internal diameter of the pipe (ft)

P1' = absolute pressure at the beginning of the pipe (Psi abs)

P2' = absolute pressure at the end of the pipe (Psi abs)

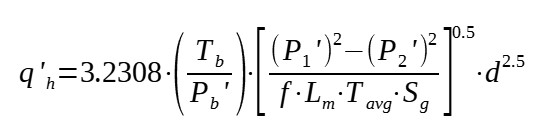

Note that there is a simplified version of the isothermal equation for gas pipelines (provided the pipe is long enough to be able to neglect the acceleration, and temperature change <= 10F) :

With :

q'h = flow of gas at standard condition (standard ft3/h)

Tb = absolute temperature at standard conditions (520 R)

Pb' = absolute pressure at standard conditions (14.7 Psi abs)

P1' = absolute pressure at the beginning of the pipe (Psi abs)

P2' = absolute pressure at the end of the pipe (Psi abs)

f = friction factor

Lm = length of pipe (miles)

Tavg = average temperature (R) - calculated as arithmetic mean in

between beginning and end of pipe if temperature does not change by

more than 10F

Sg = specific gravity of a gas relative to air = ratio of molecular

weight of the gas to that of air

d = pipe internal diameter (in)

2. Weymouth equation

The Weymouth equation can be used for gas pipelines if :

- The flow is fully turbulent

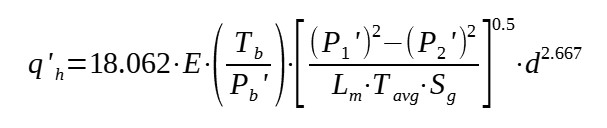

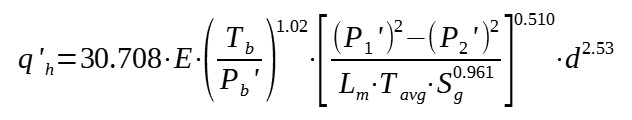

The Weymouth equation has the following form :

With :

q'h = flow of gas at standard condition (standard ft3/h)

E = efficiency factor (-)

Tb = absolute temperature at standard conditions (520 R)

Pb' = absolute pressure at standard conditions (14.7 Psi abs)

P1' = absolute pressure at the beginning of the pipe (Psi abs)

P2' = absolute pressure at the end of the pipe (Psi abs)

Lm = length of pipe (miles)

Tavg = average temperature (R) - calculated as arithmetic mean in

between beginning and end of pipe if temperature does not change by

more than 10F

Sg = specific gravity of a gas relative to air = ratio of molecular

weight of the gas to that of air

d = pipe internal diameter (in)

The efficiency factor is taking into consideration the singularities that will be present in long pipelines (valves...). It is in between 0.85 and 1. It is normally applied to Panhandle equation but it can also be applied to Weymouth equation.

Top

5 Most Popular

1. Pressure drop

2. Reynolds Number

3.

Pressure drop K coefficients

4. Churchill equation

5. Moody diagram

3. Panhandle equations

3.1 Panhandle A equation : partially turbulent flow

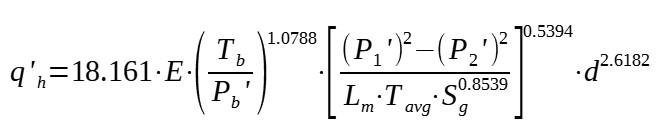

The Panhandle A equation is expressed the following way :

With :

q'h = flow of gas at standard condition (standard ft3/h)

E = efficiency factor (-)

Tb = absolute temperature at standard conditions (520 R)

Pb' = absolute pressure at standard conditions (14.7 Psi abs)

P1' = absolute pressure at the beginning of the pipe (Psi abs)

P2' = absolute pressure at the end of the pipe (Psi abs)

Lm = length of pipe (miles)

Tavg = average temperature (R) - calculated as arithmetic mean in

between beginning and end of pipe if temperature does not change by

more than 10F

Sg = specific gravity of a gas relative to air = ratio of molecular

weight of the gas to that of air

d = pipe internal diameter (in)

3.2 Panhandle B equation : Fully turbulent flow

The Panhandle B equation is expressed the following way :

With :

q'h = flow of gas at standard condition (standard ft3/h)

E = efficiency factor (-)

Tb = absolute temperature at standard conditions (520 R)

Pb' = absolute pressure at standard conditions (14.7 Psi abs)

P1' = absolute pressure at the beginning of the pipe (Psi abs)

P2' = absolute pressure at the end of the pipe (Psi abs)

Lm = length of pipe (miles)

Tavg = average temperature (R) - calculated as arithmetic mean in

between beginning and end of pipe if temperature does not change by

more than 10F

Sg = specific gravity of a gas relative to air = ratio of molecular

weight of the gas to that of air

d = pipe internal diameter (in)

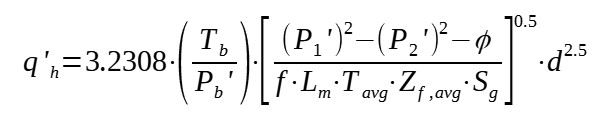

4. Modified isothermal equation

All the equations above are based on the assumption of perfect gas, it means that they are limited in their application to relatively low pressures. To be able to calculated the pressure drop at higher pressure (up to 3200 Psi g), the compressibility factor must be added to the equations. These equations also assume that the long pipe is flat which is probably not the case for very long gas pipelines, to take this into account a term of potential energy must be added.

This can be applied to the different equations expressing the volumetric flow of gas (q'h) :

- (P1')2 - (P2')2 becomes (P1')2 - (P2')2 - ϕ

- Lm*Tavg*Sg becomes Lm*Tavg*Zf,avg*Sg

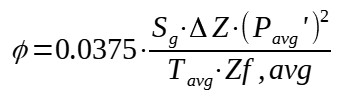

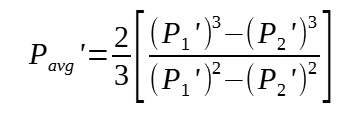

With :

ϕ = potential energy term (account for changes in elevation along

the pipe layout) =

DZ = difference of elevation along the pipe (ft)

Pavg' = average pressure =

Zf,avg = it is the compressibility factor of the gas defined at Tavg and Pavg

The compressibility factor must be calculated separately at Tavg and Pavg and used in the equation.

When those corrections are applied to the simplified isothermal equation, the new expression is then :

5. Long pipelines gas flow Excel calculator

You can access to an Excel calculation tool in order to estimate the flow of gas in long pipeline : Long pipelines gas flow calculation (click here)

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.

Source :