Plate Heat Exchangers design : calculation method

How to calculate plate heat exchangers ?

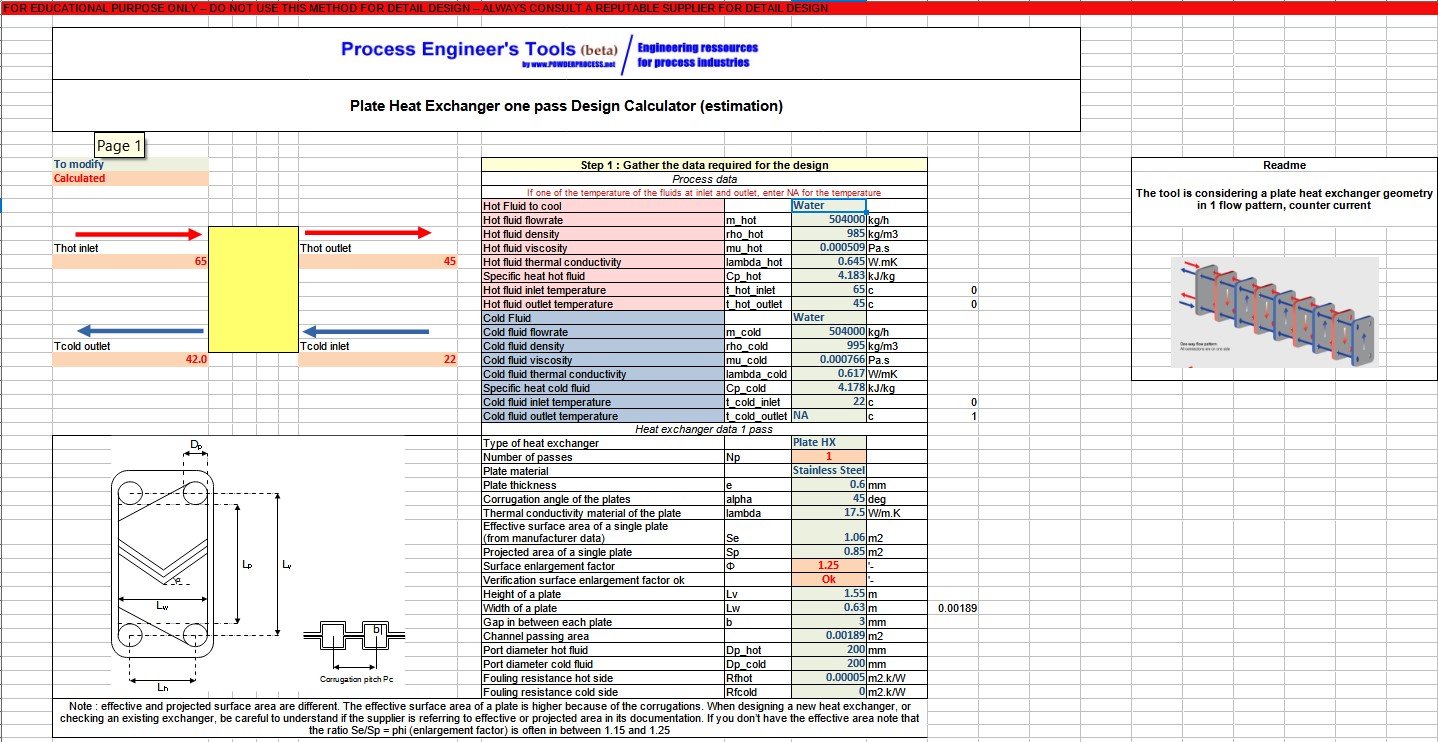

Plate Heat Exchanger Excel calculator

Follow us on Twitter ![]()

Question, remark ? Contact us at contact@myengineeringtools.com

| Section summary |

|---|

| 1. Plate heat

exchangers definition |

| 2. Calculation

procedure |

| 3. Plate heat exchanger calculator Excel |

1. Plate heat exchangers definition

What is a plate heat exchanger ?

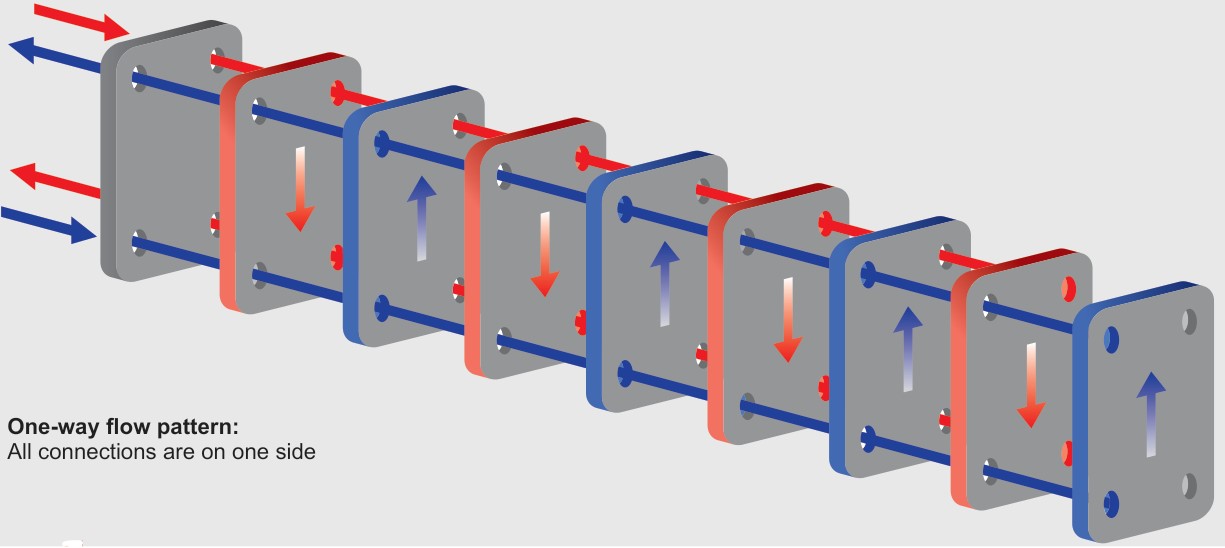

Plate and frame heat exchangers have a very specific design compared to other each exchangers : the fluid is split into wide but narrow channels in between thin plates. This allows to have a very high heat exchange coefficient and as a consequence a rather compact heat exchanger compared to other designs which can make them an interesting proposal when space or costs are a constraint. However such a design leads as a consequence to high pressure drop which will limit the application when high flow rates are involved.

Figure 1 : flow pattern in a one pass plate heat exchanger

This kind of heat exchangers have especially been popularized by the company Alfa Laval, people sometimes referring them as "Alfa Laval Plate Heat Exchanger". The most common design is to have the plates pressed against each other with gaskets in between. Such a design allows to open and clean very easily the exchanger which will be appreciable in situations where high fouling is expected or if regular cleaning is required for hygiene reasons (food industry). Using gaskets will limit the operating pressure and temperature so other designs with welded plates exist (brazed plate heat exchangers). They can operate in more extreme conditions but cannot be open for inspection and cleaning.

2. Plate heat exchanger calculation procedure : plate heat exchanger sizing

How to design a plate heat exchanger ?

The procedure below aims at designing a new plate heat exchanger, or verifying the design of an existing plate heat exchanger. It is for 1 pass heat exchangers.

2.1 STEP 1 : get the design data

The following data must be defined in order to size a plate and frame heat exchanger :

Process data

- Fluid properties (viscosity, specific heat... if possible as a function of temperature)

- Inlet and outlet temperature of each fluids (note : the procedure here is to size a heat exchanger knowing those data, but it can be adapted after, using Excel, to calculate the outlet temperature knowing the characteristics of the heat exchanger for example)

- Inlet pressure of fluids

- Allowable pressure drop

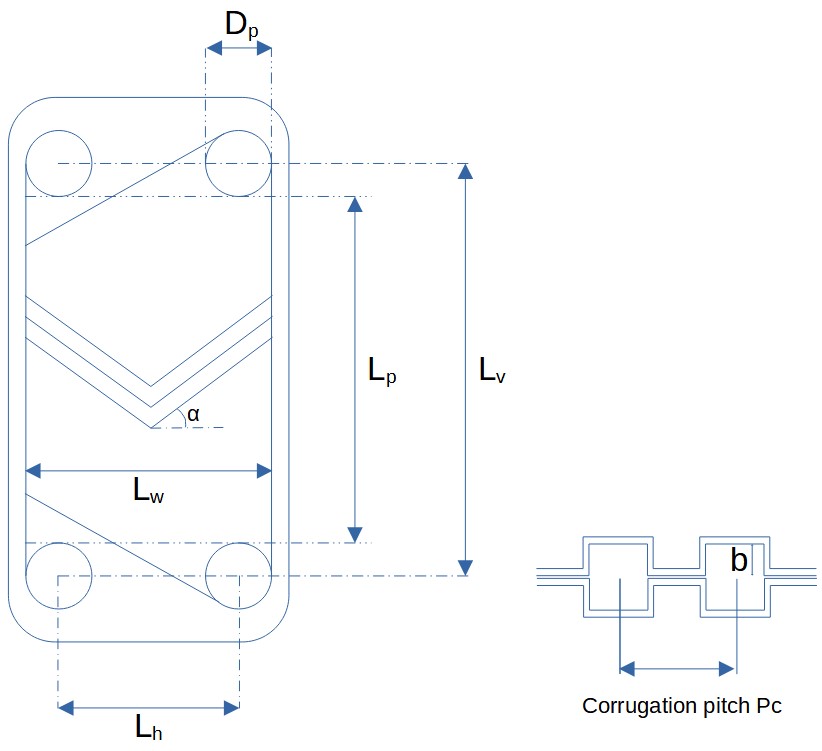

It is necessary to assume some characteristics of the heat exchanger that will be installed. Those characteristics may be changed during the iterative design process (angle of corrugation, size of the plates...), others will be fixed (material of construction). It is recommended to refer to the documentation of the suppliers to select available geometries

- Plate material (stainless steel...) and its thermal conductivity

- Plate thickness

- Angle of corrugation

- Surface are of the plates

- Dimensions of the plates

- Gap in between plates

- Fluid port diameters

- Fouling resistances

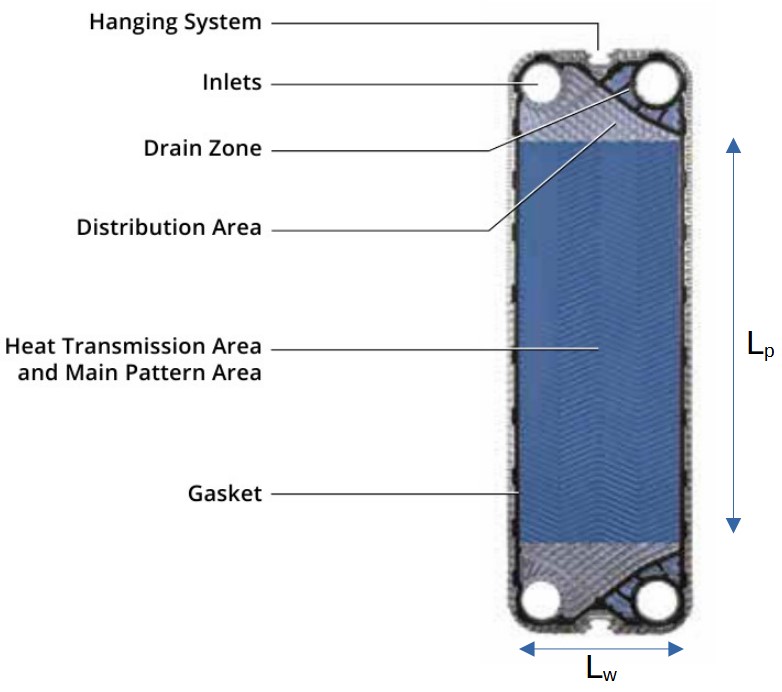

Figure 2 : characteristic dimensions of a plate heat exchangers (adapted from [Kakac])

2.2 STEP 2 : calculate the required heat flux

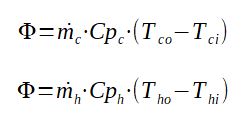

The heat flux can be calculated knowing the flowrate, the in and out temperatures and the specific heat of the fluid, either on hot or cold side.

With

mc = mass flowrate on cold side (kg/s)

Cpc = specific heat of cold fluid

Tco = outlet temperature of cold side (K)

Tci = inlet temperature of cold fluid (K)

mh = mass flowrate on hot side (kg/s)

Cph = specific heat of hot fluid (J/kg/K)

Tho = outlet temperature of hot side (K)

Thi = inlet temperature of hot fluid (K)

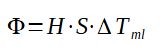

It is then possible to approximate the size of the heat exchanger by estimating the overall heat transfer coefficient H.

H for plate heat exchanger is often in between 2 to 7 kW.m-2.K-1.

H = overall heat exchange coefficient (kW.m-2.K-1)

S = effective area of the heat exchanger (m2)

ΔTml

(K)

The value of S can thus be calculated, as a 1st approximation of the heat exchanger size.

2.3 STEP 3 : calculating the number of plates required

This stage requires to have some references from suppliers, especially the size of plate they can supply, the max size of the heat exchanger when using a given plate, the design of the plate as well as the max flow the heat exchanger can handle.

From there, the Engineer can chose a plate size, design, and

calculate the number of plates required.

N = S/s

With

N = number of plates required

S = total effective heat exchange area (m2)

s = effective size of a single plate (m2)

It is also possible to calculate the number of channels : n = (N-1)/2

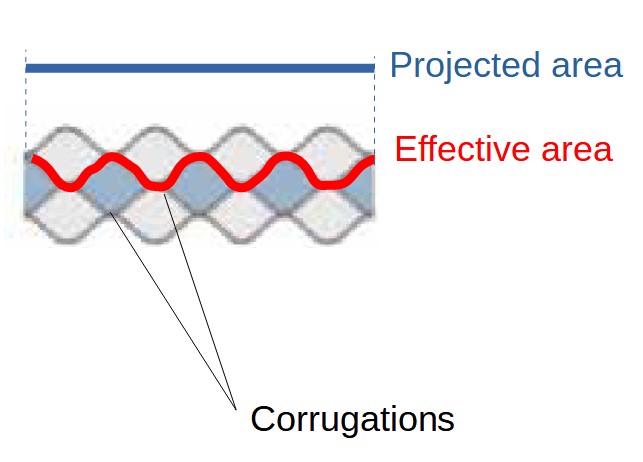

2.3.1 Effective and projected plate surface areas

It is important to understand that there is a difference in between the projected plate surface area, and the effective heat exchange surface area of a plate : this is due to the corrugations that are applied on the plates which are increasing the actual (effective) area of heat exchange.

The heat transmission area of a plate is represented on the drawing below as the blue area. The geometrical area (Lw * Lp) is the projected area.

Figure 3 : heat transmission area of

a plate

However as there are corrugations, the actual area in contact with the fluids is larger, as shown on the figure below.

Figure 4 : corrugations of a plate

and impact on effective transfer area and projected transfer area

When designing an exchanger, it is important to understand what is the surface area that is referred to in the supplier's documentation : effective or projected area ?

The ratio in between effective and projected area is called the size enlargement factor [Kakac] and is defined as :

Φ = Seff / Sproj

With :

Φ = size enlargement factor

Seff = effective heat transfer surface area (m2)

Sproj = projected heat transfer surface area (m2)

If this is not precised by the supplier, it can be assumed that the size enlargement factor is typically in between 1.15 and 1.25.

2.4 STEP 4 : confirmation of the heat exchanger size

Now that a rough design of the plate and frame heat exchanger has been done, it is required to go in details of the many options available for the plates and use correlations that will allow to recalculate the heat transfer coefficient and then a required exchange area. The calculation will then be iterative until the calculated heat exchange area is equal to the assumed area.

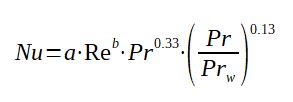

A correlation giving the Nusselt number can be used :

With

Nu = number of Nusselt (-) = h.Dh/μ

Re = Reynolds number (-) = ρ.u.Dh/μ

a = coefficient depending on the corrugation of the plates (-)

b = coefficient depending on the corrugation of the plates (-)

Pr = Prandtl number = μ.Cp/λ

Prw = Prandtl number at the plate (wall) conditions

And

h = heat transfer coefficient (W.m-2.K-1)

μ = viscosity of the fluid (Pa.s)

ρ = density of the fluid (kg/m3)

u = velocity of the fluid in between 2 plates (m/s)

Cp = specific heat of the fluid (J/kg/K)

λ = thermal conductivity (W/m/K)

Dh = hydraulic diameter = [4*l*dplate] /

[2*(l*Φ+dplate)] (m)

l = width of the plates (m)

dplate = gap in between 2 plates (m)

Φ = Size enlargement factor

a and b depends on α the angle of the corrugations on the plates. The following table is from [Aydin] which is taking its source from [Kakac]

| Corrugation angle in ° | Re | a | b |

| <30 | <10 | 0.718 | 0.349 |

| <30 | >10 | 0.348 | 0.663 |

| 45 | <10 | 0.718 | 0.349 |

| 45 | 10-100 | 0.400 | 0.598 |

| 45 | >100 | 0.300 | 0.663 |

| 50 | <20 | 0.630 | 0.333 |

| 50 | 20-300 | 0.291 | 0.591 |

| 50 | >300 | 0.130 | 0.732 |

| 60 | <20 | 0.562 | 0.326 |

| 60 | 20-400 | 0.306 | 0.529 |

| 60 | >400 | 0.108 | 0.703 |

| >65 | <20 | 0.562 | 0.326 |

| >65 | 20-500 | 0.331 | 0.503 |

| >65 | >500 | 0.087 | 0.718 |

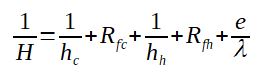

It is then possible to calculate the heat transfer coefficient h on both hot and cold side and then calculate the overall heat transfer coefficient H.

H = overall heat transfer coefficient (W.m-2.K-1)

hc = heat transfer coefficient on cold side (W.m-2.K-1)

Rfc = fouling resistance on cold side (m2.K.W-1)

hh = heat transfer coefficient on hot side (W.m-2.K-1)

Rfh = fouling resistance on hot side (m2.K.W-1)

e = thickness of the plates (m)

λ = thermal conductivity of the plate (W.m-1.K-1)

It is then required to compare H calculated with H assumed.

If Hcalculated = Hassumed, the calculation is valid, the size of the heat exchanger, with the total heat exchange area S is correct.

If Hcalculated ≠ Hassumed, then the calculation needs to be run again, this time using Hassumed as starting point, or, if values are really far, changing the design of the heat exchanger (plate size...) and running it again.

2.5 STEP 5 : Calculation of the pressure drop

The design defined in step 4 is only valid if the pressure drop on both sides is less than the allowable pressure drop. If yes, the design can be kept, if not, some design choices such as the size of the plate, corrugation, number of plates... Checking the pressure drop is especially important for gasketed plate heat exchanger which have a limited resistance to pressure compared to brazed plate heat exchangers.

2.6 STEP 6 : optimization and detail design

Even if the design done satisfies the process conditions, it may be possible to improve the design by making it less costly, more compact... the design procedure can then be re-run for the basic design calculated by changing the type of plate, size, number of plates...etc...

The procedure above will be helpful to get an idea but cannot be used to such details. It should be done with a specialized company. Detail design and construction drawing must always be done with the support of such a company.

3. Plate heat exchanger calculator Excel

The plate heat exchanger calculation method can be applied with a

plate heat exchanger calculator Excel : Plate

Heat Exchanger (PHX) calculator download (click here)

In this tool, the Pr at the wall is assumed to be very close to the

Pr of the bulk fluid (as channels are very narrow), the correction

factor (Pr/Prw) is therefore 1, please make sure it is a valid

assumption in your case.

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need. Anyone making use of the information above or in the Excel calculator does so at their own risk and assume any and all resulting liability arising therefrom.

Source

[Aydin] Report to department of chemical engineering, Middle East Technical University, Plate Heat Exchanger design, Aydin et al., 2016, https://www.slideshare.net/ervaldi/plate-type-heat-exchanger-design-62443113

[Kakac] Heat Exchangers, Selection, Rating and Thermal Design, Kakac et al, CRC Press