How to know a pipe is partially full ?

What is the liquid height and equivalent diameter ?

1. Introduction

2. Key concepts and terminology

3. Pipe full or partially filled ?

6. Practical examples

7. Calculators

1. Introduction

In process industries, it is not uncommon for pipes to be only partially full of liquid. This can occur in various scenarios, such as in return pipes or condensate lines. Assuming that a pipe is full when it is not can lead to erroneous calculations, which can have significant implications for process efficiency, safety, and cost. This article discusses a method proposed by Durand and reported by Brannan to determine if a pipe is totally full or partially full, and how to calculate the height of liquid in the pipe and the equivalent diameter.

2. Key concepts and terminology

Before delving into the calculations, it is essential to understand some key terms:

- Flow Rate (Q): The volume of fluid that passes through a given surface per unit time. It is typically measured in gallons per minute (gpm).

- Pipe Diameter (d): The internal diameter of the pipe, usually measured in inches (in).

- Height of Liquid (H): The vertical distance from the bottom of the pipe to the surface of the liquid, measured in feet (ft).

- Equivalent Diameter (De): The diameter of a hypothetical full pipe that would have the same flow characteristics as the partially full pipe, measured in feet (ft).

3. Pipe full or partially filled ?

To know if the pipe is full or not, it is necessary to calculate Q/d2.5

For sloped pipes, use the Manning formula or other open-channel shallow‑flow methods → Manning requires wetted perimeter and hydraulic radius.

4. Calculation of the Height of liquid

5. Equivalent diameter calculation

6. Practical examples

Given:

- Flow rate (Q) = 500 gpm

- Pipe diameter (d) = 10 inches

Step 1: Calculate Q/d^2.5

Q/d^2.5 = 500 / (10)^2.5 = 500 / 316.23 = 1.58

Since Q/d^2.5 < 10.2, the pipe may be partially full.

Step 2: Calculate x

x = ln(1.58) ≈ 0.457

Step 3: Calculate H/D

H/D = 0.446 + 0.272(0.457) + 0.0397(0.457)^2 - 0.0153(0.457)^3 - 0.003575(0.457)^4 ≈ 0.582

Step 4: Calculate H

H = (H/D) * D = 0.582 * (10/12) ≈ 0.485 feet

Step 5: Calculate De/D

De/D = -0.01130 + 3.040(0.582) - 3.461(0.582)^2 + 4.108(0.582)^3 - 2.638(0.582)^4 ≈ 0.786

Step 6: Calculate De

De = (De/D) * D = 0.786 * (10/12) ≈ 0.655 feet

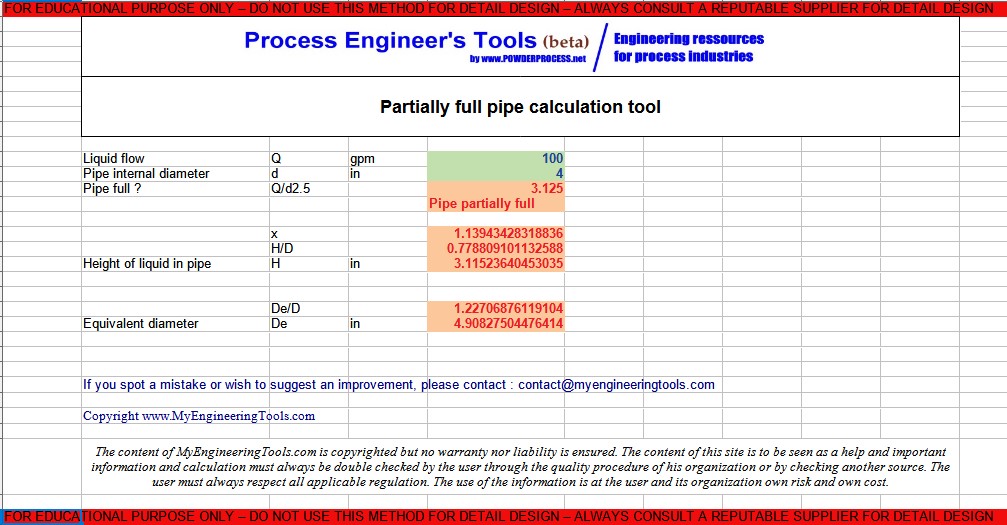

7. Calculators

7.1 Excel pipe partial flow calculator

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.

7.2 Online pipe partial flow calculator

Warning : this calculator is provided to illustrate the concepts mentioned in this webpage, it is not intended for detail design. It is not a commercial product, no guarantee is given on the results. Please consult a reputable designer for all detail design you may need.

Pipe Flow Calculator

Input Parameters

FAQ: Partially Full Pipes - Calculations and Concepts

1. How do you determine if a pipe is full or partially full?

Calculate \( \frac{Q}{d^{2.5}} \), where \( Q \) is flow rate (gpm) and \( d \) is pipe diameter (inches). If \( \frac{Q}{d^{2.5}} \geq 10.2 \), the pipe is full. If \( \frac{Q}{d^{2.5}} < 10.2 \), the pipe may be partially full, and further calculations are needed.

2. What are the key terms used in partially full pipe calculations?

Key terms include: - Flow Rate (\( Q \)): Volume of fluid per unit time (gpm). - Pipe Diameter (\( d \)): Internal diameter of the pipe (inches). - Height of Liquid (\( H \)): Vertical distance from the pipe bottom to the liquid surface (feet). - Equivalent Diameter (\( D_e \)): Diameter of a hypothetical full pipe with equivalent flow characteristics (feet).

3. When should the \( \frac{Q}{d^{2.5}} \) method be used?

This method is applicable only for horizontal, closed-flow conditions with Newtonian fluids like water. It should not be used for sloped pipes, vented systems, or multi-phase flows. Use it as a preliminary screening tool, followed by full pipe hydraulics calculations.

4. How is the height of liquid (\( H \)) in a partially full pipe calculated?

First, calculate \( x = \ln\left(\frac{Q}{d^{2.5}}\right) \). Then, use the polynomial: \[ \frac{H}{D} = 0.446 + 0.272x + 0.0397x^2 - 0.0153x^3 - 0.003575x^4 \] Finally, \( H = \frac{H}{D} \times D \), where \( D \) is pipe diameter in feet.

5. How is the equivalent diameter (\( D_e \)) calculated?

Use the polynomial: \[ \frac{D_e}{D} = -0.01130 + 3.040\left(\frac{H}{D}\right) - 3.461\left(\frac{H}{D}\right)^2 + 4.108\left(\frac{H}{D}\right)^3 - 2.638\left(\frac{H}{D}\right)^4 \] Then, \( D_e = \frac{D_e}{D} \times D \), where \( D \) is pipe diameter in feet.

6. What is the accuracy of these calculations?

The polynomial curves have an estimated accuracy of ±5–10%. They are best suited for preliminary sizing or confirming aesthetics, not final hydraulic design.

7. Can these methods be used for sloped pipes?

No, these methods are for horizontal pipes only. For sloped pipes, use open-channel flow methods like the Manning formula.

8. What are the limitations of the \( \frac{Q}{d^{2.5}} \) method?

The method is limited to horizontal, closed-flow conditions with water-like fluids. It should not be used for pipes with significant slope, venting, multi-phase flow, or sloped gravity flow.

9. Are there tools available for these calculations?

Yes, our website offers a free Excel calculator for determining if a pipe is full or partially full and calculating liquid height and equivalent diameter.

10. What precautions should be taken when using the calculator?

The calculator provides approximations for quick estimations. For detailed design, consult a reputable engineer or designer.