Viscosity of non Newtonian Fluids

1. What are non Newtonian fluids ?

2. Different types of Non Newtonian fluids

There are some fluids which exhibit particular viscosity patterns, their viscosity is not constant at any shear rate, like is the case for Newtonian fluids like water, but is changing depending on the constraint that is applied to the fluid. Those fluid are said non-Newtonian, a denomination that encompasses several viscosity behaviors. This page aims at explaining what are the most common non Newtonian viscosity patterns found by Process Engineers.

1. What are non Newtonian fluids ?

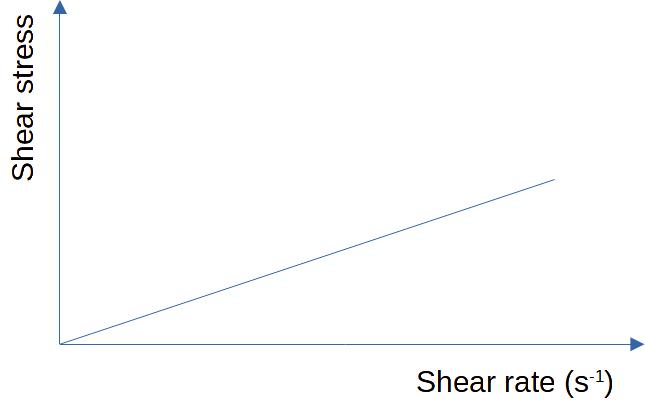

Fluids like water have a very practical characteristic for Engineers : their viscosity is independant of the shear rate (constraint) that is applied to it. If we are in laminar or turbulent flow, in pipes or in agitated vessels, the viscosity remains the same and is only dependent on temperature. Such fluids are called Newtonian, when plotting the shear stress as a function of the shear rate, we obtain a straight line, which means that the viscosity (= shear stress / shear rate) is constant.

However there are other fluids that present a totally different viscosity behavior. These are especially the case of suspensions and slurry which are holding a significant amount of finely suspended solids, as can be found in food process industries, mining industries, cosmetics and healthcare...For those fluids the shear stress resulting from different shear rate is varying, which means that the apparent viscosity is not constant.

2. Different types of Non Newtonian fluids

Non Newtonian fluids can be split in 3 main groups, each made of different types of fluids :

- Time independent Non Newtonian fluids : the apparent viscosity of the fluid is changing immediately according to the shear rate applied.

- Time dependent Non Newtonian fluids : the apparent viscosity is not only dependent on the shear rate (and the temperature - but this is always the case for any fluid), but also depends on time (when was applied the shear rate)

- Viscoelastic fluids : those materials are able to recover from deformations that happen during flow

2.1 Time independent non Newtonian fluids

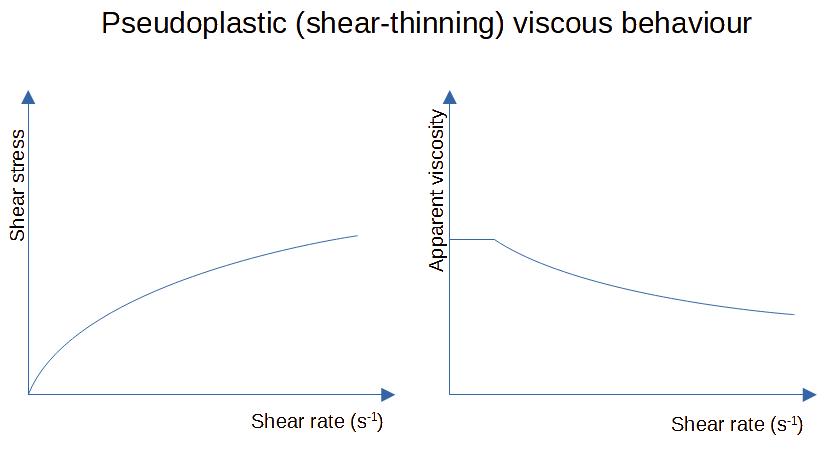

2.1.1 Shear thinning (or pseudoplastic)

For those fluids, the apparent viscosity is decreasing with the shear rate. The more the fluid is submitted to a constraint, the more its viscosity decreases. This is quite a common viscosity behavior for non newtonian fluids such as non settling suspensions, having the viscosity decrease with shear also presents some advantages for processes handling those fluids. At very low shear rate, there can be a Newtonian plateau for which the apparent viscosity is constant.

Examples of pseudoplastic materials : food slurry, paints, paper pulp, emulsions, oil and grease

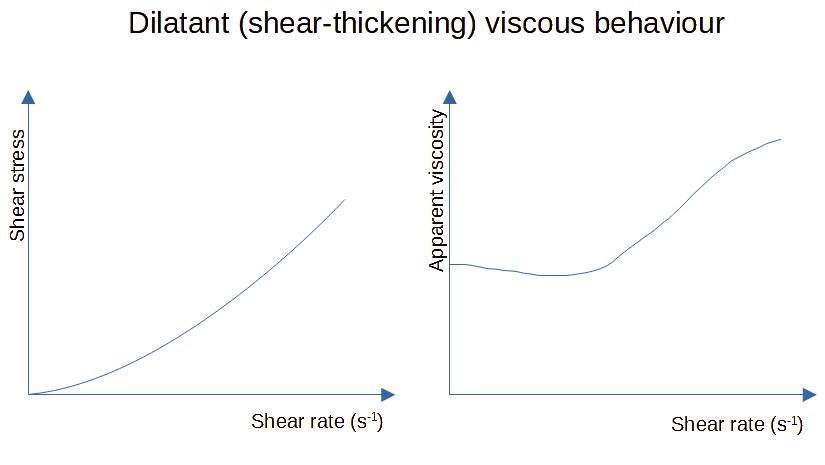

2.1.2 Shear thickening (or dilatant)

This is the opposite behavior of pseudoplastic fluids, dilatant fluids will see an increase of their apparent viscosity when the shear rate is increasing.

Example of shear thickening materials : paints, inks, quicksands

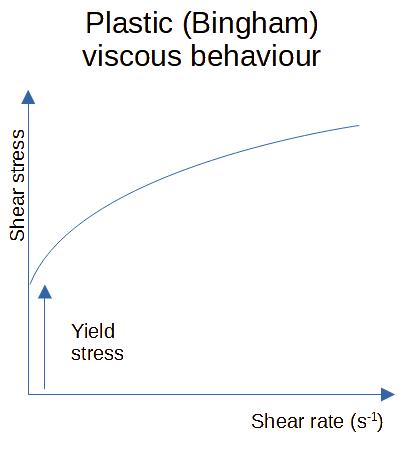

2.1.3 Bingham plastic

Bingham fluids are not flowing until a minimum shear stress is reached. This limit is called a yield stress. Once the yield stress is reached, the material begins flowing, often with a shear thinning behavior. The most common Bingham plastic is toothpaste.

Example of Bingham plastics : toothpaste, fresh cement, suspensions of metal ores in water

2.2 Time dependent non Newtonian fluids

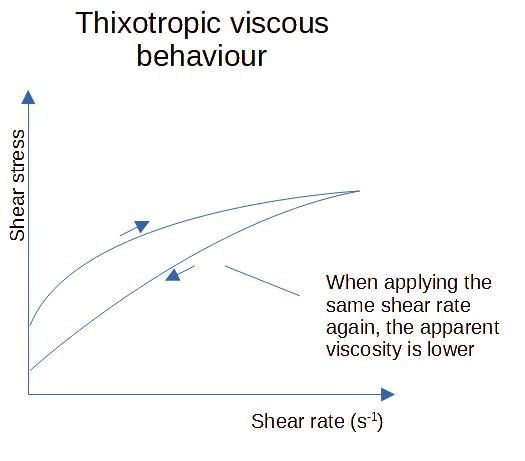

2.2.1 Thixotropic fluids

When applying a shear to the fluid, the apparent viscosity decreases, similarly to pseudoplastic materials, but as the shear is removed, the fluid showing a thixotropy behavior is not recovering its original apparent viscosity, but a lower apparent viscosity. The material's apparent viscosity even at low shear rate, is for a moment, lower. This is a very interesting property as as we can for example agitate only for a while the material, and then keep it and use it with a low viscosity.

Example of thixotropic fluids : paints, inks, ketchup, mayonnaise, chocolate

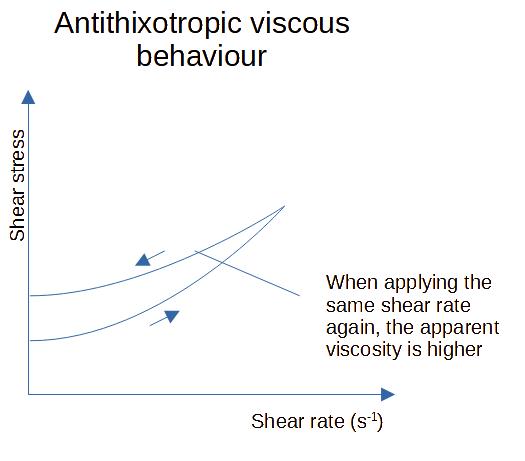

2.2.2 Antithixotropic materials (rheoplastic)

This is the exact opposite of thixotropy, after submitting the material to shear forces, the apparent viscosity is increasing, the fluid appears more and more viscous.

Example of rheoplastic materials : gypsum, paste, bentonite suspension

2.3 Viscoelastic fluids

Viscoelastic materials, while flowing, often exhibit one of the behavior shown above, especially pseudoplastic materials. However they have also the additional property to recover from deformations, similarly to elastic solids.

Examples of viscoelastic materials : polymer melts

Sources :

Handling of Bulk Solids, Shamlou, Butterworths, 1988

Principles of Powder Technology, Rhodes et al, John Wiley and Sons,

1990